👷♂️Since 2018, our teams from Sixense Northern America have been monitoring underground and surface conditions during construction of the LA Outfall as part of the hashtagClearwaterProject, in Los Angeles, California, which aims to protect local waterways by replacing aging infrastructure.

This 11.25km long, 5.5m diameter tunnel connects the Carson Wastewater Treatment Plant and the Royal Palms Beach Outfall to the ocean.

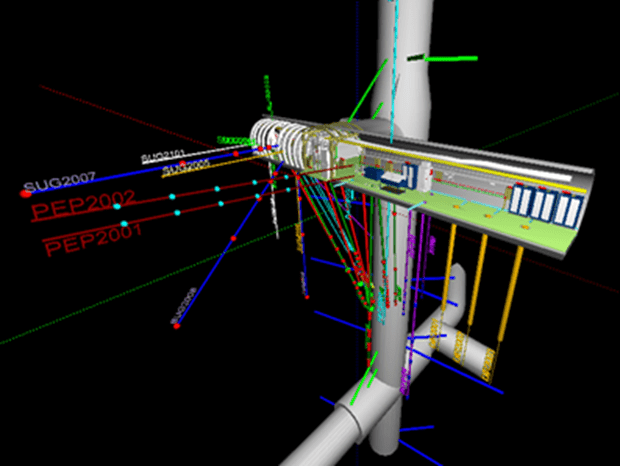

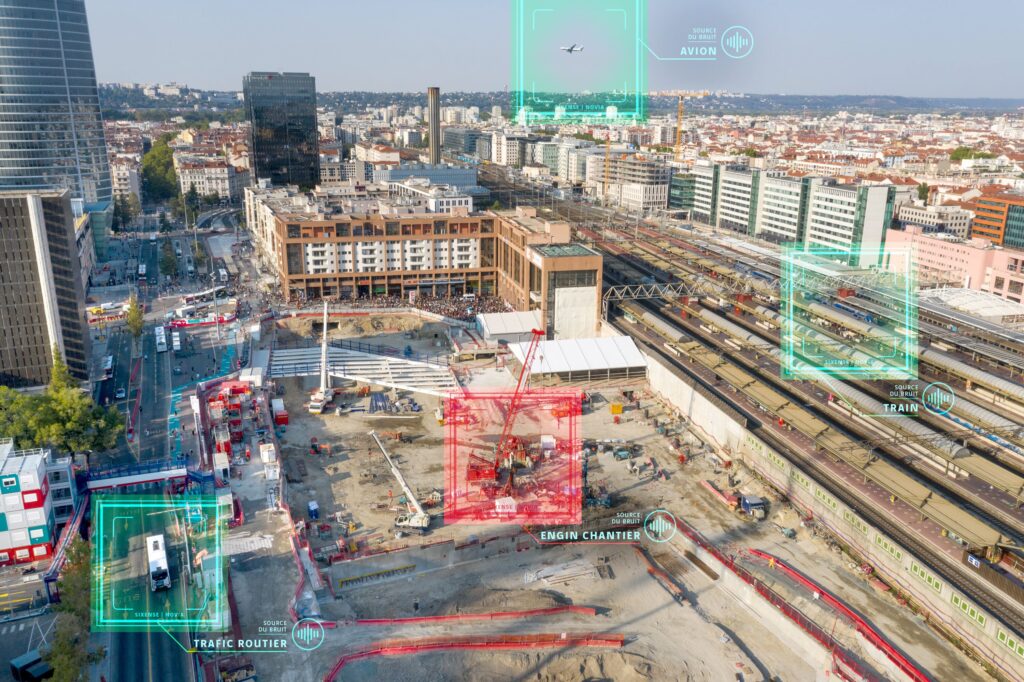

To ensure the safety of the roads, public services and neighborhoods of the city through which this tunnel passes, we are using a variety of advanced tools to monitor the works:

– 𝟲𝟳 𝗠𝗣𝗕𝗫𝘀

– 𝟭𝟭 𝗩𝗪𝗣𝗭

– 𝟴 𝗜𝗻𝗰𝗹𝗶𝗻𝗼𝗺𝗲𝘁𝗲𝗿𝘀

– 𝟭𝟬 𝗧𝗶𝗹𝘁𝗺𝗲𝘁𝗲𝗿𝘀

– 𝟮𝟳𝟮 𝗔𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗰 𝗨𝗠𝗣𝘀

– 𝟭𝟰 𝗔𝗠𝗧𝗦 (𝗖𝘆𝗰𝗹𝗼𝗽𝘀)

– 𝟭𝟯 𝗩𝗶𝗯𝗿𝗮𝘁𝗶𝗼𝗻 𝗠𝗼𝗻𝗶𝘁𝗼𝗿𝘀

– 𝟮 𝗡𝗼𝗶𝘀𝗲 𝗠𝗼𝗻𝗶𝘁𝗼𝗿𝘀

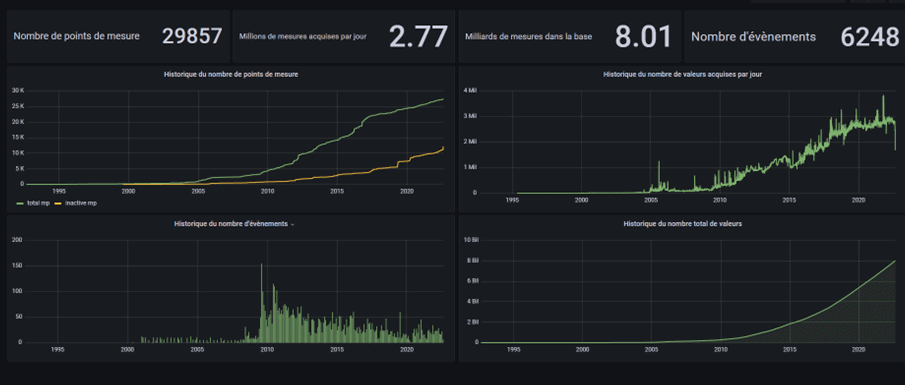

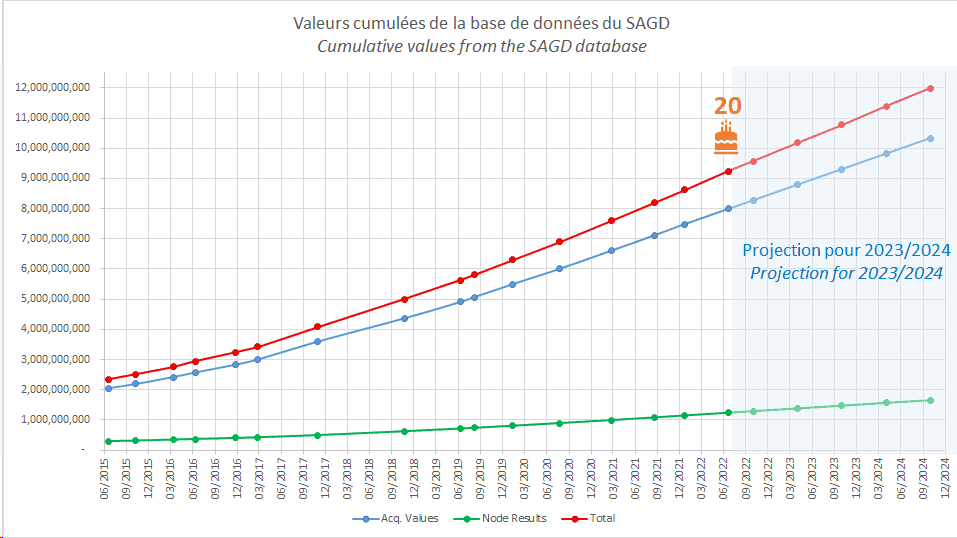

📡All the data collected is transmitted in real time via our Geoscope data management software, which integrates the position of the tunnel boring machine to correlate instrument data with the progress of the works.